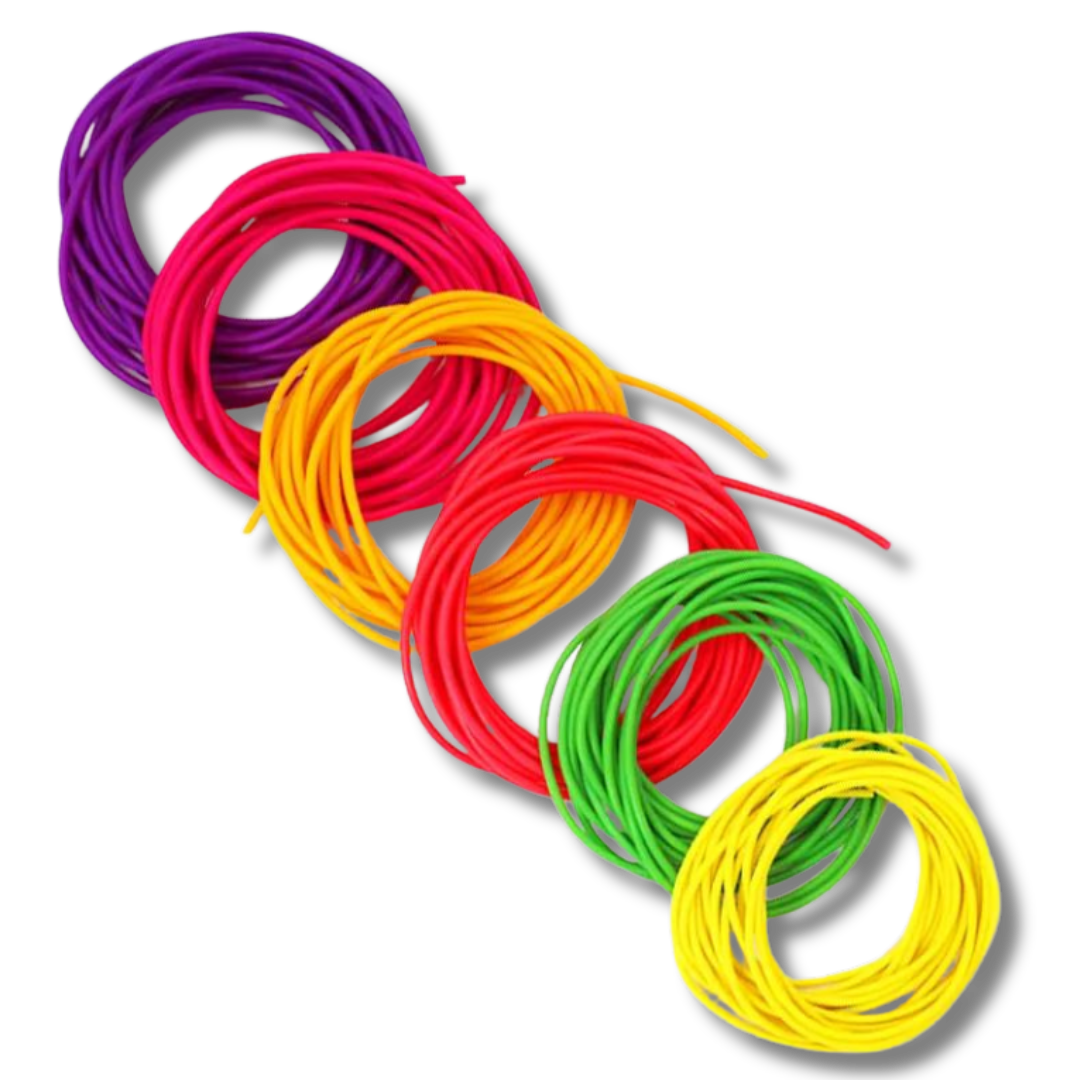

Flexible extrusion refers to a manufacturing process that involves shaping pliable materials, such as polymers or rubber compounds, through an extrusion machine. This method allows for the creation of continuous, customized shapes with varying degrees of flexibility. During the process, the material is heated and forced through a die, taking on the desired form as it solidifies. Flexible extrusion finds extensive use in producing items like hoses, tubing, seals, and gaskets, where elasticity and adaptability are essential. The versatility of this manufacturing technique makes it valuable in various industries, including automotive, construction, and electronics, providing solutions for applications that require both durability and flexibility in the end product.